Logistics engineering jobs involve the design, implementation, and maintenance of logistics systems. These systems are responsible for the efficient flow of goods and services from suppliers to customers. Logistics engineers work to ensure that products are delivered to the right place, at the right time, and at the right cost.

Logistics engineering is a critical part of the supply chain management process. It helps to ensure that businesses can meet customer demand while minimizing costs. Logistics engineers use a variety of tools and techniques to improve the efficiency of logistics systems, including:

- Data analysis

- Simulation

- Optimization

- Project management

Logistics engineers are in high demand due to the increasing complexity of global supply chains. They work in a variety of industries, including manufacturing, retail, and healthcare. Logistics engineers typically have a bachelor’s degree in industrial engineering, logistics, or a related field.

1. Planning

The planning phase is a critical part of any logistics engineer’s job. During this phase, logistics engineers must take into account a variety of factors, including cost, efficiency, and customer service. The goal of the planning phase is to create a logistics system that is both efficient and effective.

There are a number of different factors that logistics engineers must consider during the planning phase. These factors include:

- Transportation costs: Logistics engineers must consider the cost of transporting goods from suppliers to customers. This includes the cost of fuel, labor, and equipment.

- Inventory costs: Logistics engineers must also consider the cost of holding inventory. This includes the cost of storage space, insurance, and obsolescence.

- Customer service: Logistics engineers must design logistics systems that meet the needs of customers. This includes factors such as delivery time, accuracy, and reliability.

Logistics engineers use a variety of tools and techniques to plan and design logistics systems. These tools and techniques include:

- Data analysis: Logistics engineers use data analysis to identify trends and patterns in the supply chain. This data can be used to improve the efficiency of logistics systems.

- Simulation: Logistics engineers use simulation to model logistics systems. This allows them to test different scenarios and identify potential problems.

- Optimization: Logistics engineers use optimization techniques to improve the efficiency of logistics systems. This can involve reducing costs, improving delivery times, or increasing customer satisfaction.

The planning phase is a critical part of any logistics engineer’s job. By taking into account all of the relevant factors, logistics engineers can create logistics systems that are both efficient and effective.

2. Implementation

The implementation phase is a critical part of any logistics engineer’s job. During this phase, logistics engineers must put the logistics system into action and ensure that it operates smoothly and efficiently. This involves a variety of tasks, including:

- Developing operating procedures: Logistics engineers must develop operating procedures for the logistics system. These procedures should include instructions on how to operate the system, how to handle exceptions, and how to maintain the system.

- Training staff: Logistics engineers must train staff on how to operate the logistics system. This training should include both classroom instruction and on-the-job training.

- Monitoring the system: Logistics engineers must monitor the logistics system to ensure that it is operating smoothly and efficiently. This involves tracking key performance indicators (KPIs) and identifying any potential problems.

- Making adjustments: Logistics engineers must make adjustments to the logistics system as needed. These adjustments may be necessary to improve efficiency, reduce costs, or meet changing customers.

The implementation phase is a critical part of any logistics engineer’s job. By following these steps, logistics engineers can ensure that the logistics system operates smoothly and efficiently.

3. Optimization

Optimization is a critical part of logistics engineering. Logistics engineers use data analysis and other tools to identify areas where logistics systems can be improved. This can involve reducing costs, improving delivery times, or increasing customer satisfaction.

There are a number of different ways that logistics engineers can optimize logistics systems. Some of the most common methods include:

- Data analysis: Logistics engineers use data analysis to identify trends and patterns in the supply chain. This data can be used to identify areas where the logistics system can be improved.

- Simulation: Logistics engineers use simulation to model logistics systems. This allows them to test different scenarios and identify potential problems.

- Optimization: Logistics engineers use optimization techniques to improve the efficiency of logistics systems. This can involve reducing costs, improving delivery times, or increasing customer satisfaction.

Optimization is a continuous process. Logistics engineers must constantly monitor the logistics system and identify areas where it can be improved. By doing so, logistics engineers can ensure that the logistics system is operating at peak efficiency.

Here is an example of how optimization can be used to improve a logistics system. A logistics engineer might use data analysis to identify that a particular warehouse is operating at capacity. The logistics engineer could then use simulation to model different scenarios to see how the warehouse could be reconfigured to improve efficiency. The logistics engineer could then implement the changes and monitor the results to see if the efficiency of the warehouse has improved.

Optimization is a critical part of logistics engineering. By using data analysis and other tools to optimize logistics systems, logistics engineers can improve efficiency, reduce costs, and increase customer satisfaction.

4. Technology

Technology plays a vital role in logistics engineer jobs. Logistics engineers use a variety of technologies to improve the efficiency of logistics systems, including transportation management systems (TMS), warehouse management systems (WMS), and inventory management systems (IMS)

- Transportation management systems (TMS): TMSs help logistics engineers plan, execute, and track the movement of goods from suppliers to customers. TMSs can be used to optimize shipping routes, reduce transportation costs, and improve customer service.

- Warehouse management systems (WMS): WMSs help logistics engineers manage the day-to-day operations of warehouses. WMSs can be used to track inventory levels, optimize warehouse space, and improve picking and packing operations.

- Inventory management systems (IMS): IMSs help logistics engineers manage the flow of inventory throughout the supply chain. IMSs can be used to track inventory levels, forecast demand, and optimize inventory replenishment.

The use of technology in logistics engineer jobs has led to a number of benefits, including:

- Increased efficiency: Technology has helped logistics engineers to improve the efficiency of logistics systems. This has led to reduced costs, improved customer service, and increased profits.

- Improved visibility: Technology has given logistics engineers greater visibility into the supply chain. This has helped them to identify and address problems more quickly.

- Increased collaboration: Technology has made it easier for logistics engineers to collaborate with other members of the supply chain. This has led to improved coordination and efficiency.

The use of technology is essential for logistics engineers to be successful in today’s competitive business environment. Technology can help logistics engineers to improve the efficiency of logistics systems, reduce costs, and improve customer service.

Here is an example of how technology is used in logistics engineer jobs. A logistics engineer might use a TMS to plan the shipment of a product from a supplier to a customer. The TMS would help the logistics engineer to find the most efficient shipping route and the best carrier. The logistics engineer could then use a WMS to track the shipment and ensure that it is delivered to the customer on time and in good condition.

Technology is a critical part of logistics engineer jobs. Logistics engineers use technology to improve the efficiency of logistics systems, reduce costs, and improve customer service.

5. Communication

Communication is a critical skill for logistics engineers. They must be able to communicate effectively with a variety of stakeholders, including customers, suppliers, and transportation providers. This is because logistics engineers are responsible for the planning, implementation, and management of logistics systems. These systems are responsible for the efficient flow of goods and services from suppliers to customers.

There are a number of reasons why communication is so important for logistics engineers. First, logistics engineers must be able to communicate their plans and ideas to other members of the supply chain. This includes communicating with customers to understand their needs, communicating with suppliers to ensure that they can meet those needs, and communicating with transportation providers to ensure that goods are delivered on time and in good condition.

Second, logistics engineers must be able to resolve problems that arise during the transportation and delivery of goods. This may involve communicating with customers to resolve order issues, communicating with suppliers to resolve production issues, or communicating with transportation providers to resolve delivery issues.

Finally, logistics engineers must be able to communicate the status of logistics systems to management. This includes providing regular updates on the progress of shipments, identifying any potential problems, and recommending solutions to improve the efficiency of logistics systems.

Effective communication is essential for logistics engineers to be successful. By communicating effectively with all stakeholders, logistics engineers can ensure that goods are delivered to the right place, at the right time, and at the right cost.

Here are some examples of how communication is used in logistics engineer jobs:

- A logistics engineer might communicate with a customer to understand their needs for a new product. The logistics engineer would then communicate these needs to the supplier to ensure that the supplier can meet those needs.

- A logistics engineer might communicate with a transportation provider to negotiate a shipping rate. The logistics engineer would then communicate this rate to the customer so that the customer can factor it into their pricing.

- A logistics engineer might communicate with a supplier to resolve a production issue. The logistics engineer would then communicate the status of the issue to the customer so that the customer can adjust their expectations accordingly.

These are just a few examples of how communication is used in logistics engineer jobs. Effective communication is essential for logistics engineers to be successful in their roles.

6. Problem-solving

Problem-solving is a critical skill for logistics engineers. They must be able to quickly and efficiently identify and resolve problems that arise during the planning, implementation, and management of logistics systems. These problems can be caused by a variety of factors, such as delays in shipping, production issues, or changes in customer demand.

Logistics engineers must be able to think critically and creatively to find solutions to these problems. They must also be able to communicate effectively with all stakeholders involved in the supply chain, including customers, suppliers, and transportation providers.

The ability to solve problems quickly and efficiently is essential for logistics engineers to be successful in their roles. By being able to quickly identify and resolve problems, logistics engineers can ensure that goods are delivered to the right place, at the right time, and at the right cost.

Here are some examples of how problem-solving is used in logistics engineer jobs:

- A logistics engineer might be faced with a problem where a shipment of goods is delayed due to a weather event. The logistics engineer would need to quickly identify alternative shipping routes or modes of transportation to ensure that the goods are delivered to the customer on time.

- A logistics engineer might be faced with a problem where a supplier is unable to meet the demand for a particular product. The logistics engineer would need to quickly identify alternative suppliers or find ways to increase the production capacity of the existing supplier.

- A logistics engineer might be faced with a problem where a customer changes their order at the last minute. The logistics engineer would need to quickly adjust the logistics plan to accommodate the changes and ensure that the customer’s needs are met.

These are just a few examples of how problem-solving is used in logistics engineer jobs. The ability to solve problems quickly and efficiently is essential for logistics engineers to be successful in their roles.

7. Teamwork

Teamwork is essential for the success of logistics engineers. They must be able to collaborate effectively with other members of the supply chain, including customers, suppliers, and transportation providers. In addition, logistics engineers often work as part of a team within their own organization. This team may include other engineers, managers, and staff.

There are a number of reasons why teamwork is so important for logistics engineers. First, logistics is a complex and challenging field. There are many different factors that can affect the flow of goods and services, and it is important for logistics engineers to be able to work together to identify and solve problems.

Second, teamwork can help to improve the efficiency of logistics systems. By working together, logistics engineers can share ideas and knowledge, and they can develop more innovative and effective solutions.

Finally, teamwork can help to build relationships between logistics engineers and other members of the supply chain. These relationships can be valuable in times of crisis, when it is important to be able to rely on others for help.

Here are some examples of how teamwork is used in logistics engineer jobs:

- A logistics engineer might work with a team of other engineers to design a new logistics system. The team would work together to identify the customer’s needs, develop a plan for the system, and implement the system.

- A logistics engineer might work with a team of managers to develop a new logistics strategy. The team would work together to identify the company’s goals, develop a plan to achieve those goals, and implement the plan.

- A logistics engineer might work with a team of staff to implement a new logistics system. The team would work together to train staff on the new system, troubleshoot any problems, and ensure that the system is running smoothly.

These are just a few examples of how teamwork is used in logistics engineer jobs. Teamwork is essential for the success of logistics engineers, and it can help to improve the efficiency of logistics systems, build relationships, and solve problems.

8. Continuous improvement

Continuous improvement is a key aspect of logistics engineer jobs. Logistics engineers are constantly seeking ways to improve the efficiency and effectiveness of logistics systems. This is because logistics systems are complex and constantly changing, and there is always room for improvement.

- Process improvement: Logistics engineers use a variety of process improvement tools and techniques to identify and eliminate waste in logistics systems. This can involve streamlining processes, reducing cycle times, and improving communication and coordination.

- Technology adoption: Logistics engineers are constantly evaluating new technologies that can improve the efficiency of logistics systems. This includes technologies such as transportation management systems, warehouse management systems, and inventory management systems.

- Data analysis: Logistics engineers use data analysis to identify trends and patterns in logistics systems. This data can be used to identify areas for improvement and to develop new strategies.

- Collaboration: Logistics engineers work with other members of the supply chain to identify and implement improvements. This includes collaboration with customers, suppliers, and transportation providers.

Continuous improvement is essential for logistics engineers to be successful in their roles. By constantly seeking ways to improve the efficiency and effectiveness of logistics systems, logistics engineers can help to reduce costs, improve customer service, and increase profits.

FAQs about Logistics Engineer Jobs

Logistics engineers play a vital role in the global supply chain, ensuring that goods and services are delivered to the right place, at the right time, and at the right cost. Here are some frequently asked questions about logistics engineer jobs:

Question 1: What is a logistics engineer?

A logistics engineer is responsible for the planning, implementation, and management of logistics systems. Logistics systems involve the efficient flow of goods and services from suppliers to customers.

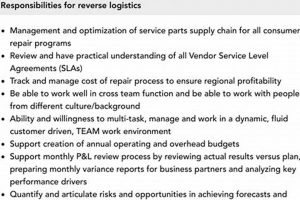

Question 2: What are the responsibilities of a logistics engineer?

The responsibilities of a logistics engineer can include:

- Planning and designing logistics systems

- Implementing and managing logistics systems

- Optimizing logistics systems

- Using technology to improve the efficiency of logistics systems

- Communicating with stakeholders

- Solving problems

- Working in a team

- Continuous improvement

Question 3: What are the benefits of a logistics engineer job?

There are many benefits to a logistics engineer job, including:

- Job security: The demand for logistics engineers is high and is expected to continue to grow in the future.

- Good salary: Logistics engineers earn a good salary, with the median annual salary being over $75,000.

- Variety: Logistics engineers work on a variety of projects, which can keep the job interesting.

- Challenge: Logistics engineers are constantly challenged to find new and innovative ways to improve the efficiency of logistics systems.

- Making a difference: Logistics engineers play a vital role in the global supply chain, and their work helps to ensure that goods and services are delivered to consumers safely, efficiently, and cost-effectively.

Question 4: What are the qualifications for a logistics engineer job?

The qualifications for a logistics engineer job typically include:

- A bachelor’s degree in industrial engineering, logistics, or a related field

- Experience in logistics or supply chain management

- Strong analytical and problem-solving skills

- Excellent communication and interpersonal skills

Question 5: What is the career outlook for logistics engineers?

The career outlook for logistics engineers is positive. The demand for logistics engineers is expected to continue to grow in the future, as businesses increasingly rely on efficient and effective logistics systems to compete in the global marketplace.

Question 6: What are some tips for becoming a successful logistics engineer?

Here are some tips for becoming a successful logistics engineer:

- Get a good education

- Gain experience in logistics or supply chain management

- Develop strong analytical and problem-solving skills

- Develop excellent communication and interpersonal skills

- Stay up-to-date on the latest trends in logistics and supply chain management

By following these tips, you can increase your chances of becoming a successful logistics engineer.

Logistics engineer jobs are essential for the efficient functioning of the global supply chain. Logistics engineers play a vital role in ensuring that goods and services are delivered to the right place, at the right time, and at the right cost. If you are interested in a career in logistics, then a logistics engineer job may be the right choice for you.

—

Transition to the next article section:

Now that you have learned about logistics engineer jobs, you may be wondering how to get started in this field. The next section of this article will provide you with some tips on how to become a logistics engineer.

Tips for Becoming a Successful Logistics Engineer

Logistics engineers play a vital role in the global supply chain, ensuring that goods and services are delivered to the right place, at the right time, and at the right cost. If you are interested in a career in logistics, then following these tips can increase your chances of becoming a successful logistics engineer:

Tip 1: Get a Good Education

A strong educational foundation is essential for a successful career as a logistics engineer. A bachelor’s degree in industrial engineering, logistics, or a related field will provide you with the knowledge and skills you need to succeed in this field.

Tip 2: Gain Experience in Logistics or Supply Chain Management

Practical experience is essential for success in logistics engineering. Internships, co-ops, and entry-level jobs in logistics or supply chain management can provide you with the hands-on experience you need to succeed. This experience will also help you to develop a network of contacts in the industry.

Tip 3: Develop Strong Analytical and Problem-Solving Skills

Logistics engineers must be able to analyze complex data and solve problems quickly and efficiently. Take courses in mathematics, statistics, and operations research to develop these skills.

Tip 4: Develop Excellent Communication and Interpersonal Skills

Logistics engineers must be able to communicate effectively with a variety of stakeholders, including customers, suppliers, and transportation providers. Develop your communication and interpersonal skills through coursework, clubs, and volunteer activities.

Tip 5: Stay Up-to-Date on the Latest Trends in Logistics and Supply Chain Management

The field of logistics and supply chain management is constantly evolving. Stay up-to-date on the latest trends by reading industry publications, attending conferences, and taking continuing education courses.

Tip 6: Get Certified

There are a number of professional certifications available for logistics engineers. Getting certified can demonstrate your commitment to the profession and your knowledge of the latest trends and best practices.

Tip 7: Network with Other Logistics Engineers

Networking is important for career success in any field, and logistics engineering is no exception. Attend industry events, join professional organizations, and connect with other logistics engineers on LinkedIn.

Tip 8: Be Passionate About Logistics

Logistics engineering is a challenging but rewarding field. To be successful, you need to be passionate about logistics and have a strong desire to make a difference in the global supply chain.

By following these tips, you can increase your chances of becoming a successful logistics engineer.

—

Conclusion:

A career as a logistics engineer can be both challenging and rewarding. By following the tips outlined in this article, you can increase your chances of success in this field.

Conclusion

Logistics engineer jobs play a critical role in the global supply chain, ensuring that goods and services are delivered to the right place, at the right time, and at the right cost. The demand for logistics engineers is high and is expected to continue to grow in the future. Logistics engineers with a strong educational background, practical experience, and a passion for logistics are well-positioned for success in this field.

If you are interested in a career in logistics, then consider pursuing a degree in industrial engineering, logistics, or a related field. Gain experience in logistics or supply chain management through internships, co-ops, or entry-level jobs. Develop your analytical, problem-solving, communication, and interpersonal skills. Stay up-to-date on the latest trends in logistics and supply chain management. Network with other logistics engineers and get certified to demonstrate your commitment to the profession.

By following these tips, you can increase your chances of becoming a successful logistics engineer and making a significant contribution to the global supply chain.