Operations and logistics jobs encompass a wide range of responsibilities within businesses and organizations. These roles involve planning, organizing, and executing activities to ensure the efficient and effective flow of goods, services, and information.

Operations and logistics professionals play a vital role in ensuring that businesses run smoothly and efficiently. They are responsible for managing supply chains, coordinating production and distribution, and ensuring that customer orders are fulfilled on time and within budget. In addition, they work to improve efficiency and reduce costs, which can help businesses gain a competitive advantage.

There are many different types of operations and logistics jobs, including:

- Supply chain managers

- Logisticians

- Operations managers

- Production planners

- Inventory control specialists

- Distribution center managers

- Transportation managers

Operations and logistics jobs are essential for the smooth functioning of businesses and organizations. They offer a variety of career opportunities for individuals with a variety of skills and interests.

1. Planning

Planning is essential for the success of any operations and logistics function. By planning effectively, businesses can avoid costly mistakes and ensure that their operations run smoothly.

- Demand forecasting

Demand forecasting is the process of predicting future demand for a product or service. This information is essential for planning production and inventory levels. In operations and logistics, demand forecasting is used to ensure that businesses have the right amount of inventory on hand to meet customer demand, without overstocking or understocking.

- Production planning

Production planning is the process of planning the production of goods or services. This involves determining the quantity of goods or services to be produced, the production schedule, and the resources that will be required. In operations and logistics, production planning is used to ensure that businesses can meet customer demand while also minimizing costs.

- Inventory management

Inventory management is the process of managing the inventory of goods or services. This involves determining the optimal inventory levels, the storage of inventory, and the replenishment of inventory. In operations and logistics, inventory management is used to ensure that businesses have the right amount of inventory on hand to meet customer demand, without overstocking or understocking.

- Transportation planning

Transportation planning is the process of planning the transportation of goods or services. This involves determining the mode of transportation, the shipping routes, and the transportation schedule. In operations and logistics, transportation planning is used to ensure that businesses can transport goods or services to customers in a timely and cost-effective manner.

By effectively planning their operations and logistics activities, businesses can improve their efficiency, reduce costs, and gain a competitive advantage.

2. Organizing

Organizing is essential for the success of any operations and logistics function. By organizing their resources efficiently, businesses can improve productivity and reduce waste.

- Workforce management

Workforce management is the process of planning, organizing, and managing the workforce. This involves determining the number of employees needed, the skills and qualifications required, and the work schedules. In operations and logistics, workforce management is used to ensure that businesses have the right number of employees with the right skills to meet customer demand.

- Equipment management

Equipment management is the process of planning, organizing, and managing the equipment used in operations and logistics. This involves determining the type of equipment needed, the quantity of equipment required, and the maintenance schedule. In operations and logistics, equipment management is used to ensure that businesses have the right equipment to meet customer demand while also minimizing costs.

- Facility management

Facility management is the process of planning, organizing, and managing the facilities used in operations and logistics. This involves determining the type of facilities needed, the size of the facilities, and the location of the facilities. In operations and logistics, facility management is used to ensure that businesses have the right facilities to meet customer demand while also minimizing costs.

- Information management

Information management is the process of planning, organizing, and managing the information used in operations and logistics. This involves determining the type of information needed, the format of the information, and the storage of the information. In operations and logistics, information management is used to ensure that businesses have the right information to make decisions and manage their operations effectively.

By effectively organizing their operations and logistics activities, businesses can improve their efficiency, reduce costs, and gain a competitive advantage.

3. Executing

Executing is essential for the success of any operations and logistics function. It involves carrying out the plans that have been made and ensuring that they are executed effectively and efficiently.

- Planning and Execution

The first step in executing operations and logistics plans is to ensure that they are well-planned and thought out. This involves considering all of the factors that could affect the execution of the plan, such as the availability of resources, the skills and experience of the team, and the potential risks involved. Once the plan is in place, it is important to execute it effectively and efficiently. This involves setting clear goals and objectives, communicating the plan to the team, and providing the necessary support and resources to ensure that the plan is executed successfully.

- Communication and Coordination

Communication and coordination are essential for the successful execution of operations and logistics plans. This involves keeping all stakeholders informed of the plan and its progress, and ensuring that everyone is working together towards the same goals. It is also important to be able to adapt the plan as needed, based on feedback from the team and changes in the environment.

- Decision-Making

Decision-making is a critical part of executing operations and logistics plans. This involves making decisions about how to allocate resources, how to respond to changes in the environment, and how to resolve problems. It is important to make decisions quickly and effectively, based on the best available information.

- Problem-Solving

Problem-solving is another important part of executing operations and logistics plans. This involves identifying problems, analyzing the causes of the problems, and developing and implementing solutions. It is important to be able to solve problems quickly and effectively, in order to minimize the impact on the plan.

By effectively executing their operations and logistics plans, businesses can improve their efficiency, reduce costs, and gain a competitive advantage.

4. Managing

Managing is essential for the success of any operations and logistics function. It involves planning, organizing, directing, and controlling the activities of an organization to achieve its goals and objectives. In the context of operations and logistics, managing involves overseeing the planning, execution, and control of the flow of goods, services, and information within an organization.

Effective management of operations and logistics is critical for businesses to achieve their goals. By effectively managing their operations and logistics functions, businesses can improve their efficiency, reduce costs, and gain a competitive advantage. For example, by effectively managing their supply chain, businesses can reduce inventory costs and improve customer service. By effectively managing their transportation and distribution networks, businesses can reduce shipping costs and improve delivery times.

There are many different aspects to managing operations and logistics, including:

- Planning: This involves developing a plan for how to achieve the organization’s goals and objectives. The plan should include a description of the organization’s operations and logistics activities, as well as a timeline for achieving the goals and objectives.

- Organizing: This involves creating a structure for the organization’s operations and logistics activities. The structure should define the roles and responsibilities of the employees involved in these activities, as well as the relationships between the different departments and units.

- Directing: This involves leading and motivating the employees involved in operations and logistics activities. The manager should provide clear direction and support to the employees, and should create a positive work environment.

- Controlling: This involves monitoring the performance of the organization’s operations and logistics activities and taking corrective action when necessary. The manager should track key performance indicators (KPIs) to measure the performance of these activities, and should make adjustments to the plan as needed.

By effectively managing their operations and logistics functions, businesses can improve their efficiency, reduce costs, and gain a competitive advantage.

5. Coordinating

Coordinating is a critical component of operations and logistics jobs. It involves the ability to plan, organize, and execute activities in a way that ensures that all parts of the operation are working together smoothly and efficiently. In the context of operations and logistics, coordinating involves managing the flow of goods, services, and information between different departments and units within an organization, as well as with external partners such as suppliers and customers.

Effective coordination is essential for the success of any operations and logistics function. By effectively coordinating their activities, businesses can improve their efficiency, reduce costs, and gain a competitive advantage. For example, by effectively coordinating their supply chain, businesses can reduce inventory costs and improve customer service. By effectively coordinating their transportation and distribution networks, businesses can reduce shipping costs and improve delivery times.

There are many different aspects to coordinating operations and logistics, including:

- Planning: This involves developing a plan for how to achieve the organization’s goals and objectives. The plan should include a description of the organization’s operations and logistics activities, as well as a timeline for achieving the goals and objectives.

- Organizing: This involves creating a structure for the organization’s operations and logistics activities. The structure should define the roles and responsibilities of the employees involved in these activities, as well as the relationships between the different departments and units.

- Directing: This involves leading and motivating the employees involved in operations and logistics activities. The manager should provide clear direction and support to the employees, and should create a positive work environment.

- Controlling: This involves monitoring the performance of the organization’s operations and logistics activities and taking corrective action when necessary. The manager should track key performance indicators (KPIs) to measure the performance of these activities, and should make adjustments to the plan as needed.

Coordinating is a complex and challenging task, but it is essential for the success of any operations and logistics function. By effectively coordinating their activities, businesses can improve their efficiency, reduce costs, and gain a competitive advantage.

6. Improving

Improving is a key aspect of operations and logistics jobs. It involves identifying areas for improvement, developing and implementing solutions, and monitoring the results to ensure that the improvements are sustained. There are many different ways to improve operations and logistics, and the best approach will vary depending on the specific circumstances.

- Process Improvement

One common way to improve operations and logistics is to focus on process improvement. This involves identifying and analyzing existing processes, and then making changes to improve efficiency and effectiveness. For example, a company might identify that its order fulfillment process is taking too long and costing too much. By analyzing the process, the company might identify several areas for improvement, such as automating certain tasks or streamlining the flow of information. By implementing these improvements, the company could reduce the time and cost of order fulfillment.

- Technology Implementation

Another way to improve operations and logistics is to implement new technologies. Technology can be used to automate tasks, improve communication and coordination, and track performance. For example, a company might implement a new inventory management system to track inventory levels in real time. This would allow the company to better manage its inventory, reduce waste, and improve customer service.

- Employee Training

Another important way to improve operations and logistics is to invest in employee training. Well-trained employees are more productive and efficient, and they are better able to identify and solve problems. For example, a company might provide training on new equipment or software to its employees. This would allow the employees to use the new equipment or software more effectively, which would lead to improved productivity and efficiency.

- Continuous Improvement

Improving operations and logistics is an ongoing process. There is always room for improvement, and companies should continuously look for ways to improve their operations. This can be done by regularly reviewing performance, identifying areas for improvement, and implementing solutions. By continuously improving their operations and logistics, companies can gain a competitive advantage and improve their bottom line.

Improving operations and logistics is essential for businesses to succeed in today’s competitive environment. By investing in process improvement, technology implementation, employee training, and continuous improvement, companies can improve their efficiency, reduce costs, and gain a competitive advantage.

7. Reducing

Reducing is a key aspect of operations and logistics jobs. It involves identifying areas where costs can be cut, waste can be eliminated, and efficiency can be improved. There are many different ways to reduce costs in operations and logistics, and the best approach will vary depending on the specific circumstances.

One common way to reduce costs is to focus on process improvement. By identifying and eliminating unnecessary steps in processes, businesses can save time and money. For example, a company might identify that its order fulfillment process is taking too long and costing too much. By analyzing the process, the company might identify several areas for improvement, such as automating certain tasks or streamlining the flow of information. By implementing these improvements, the company could reduce the time and cost of order fulfillment.

Another way to reduce costs is to implement new technologies. Technology can be used to automate tasks, improve communication and coordination, and track performance. For example, a company might implement a new inventory management system to track inventory levels in real time. This would allow the company to better manage its inventory, reduce waste, and improve customer service.

Employee training is another important way to reduce costs. Well-trained employees are more productive and efficient, and they are better able to identify and solve problems. For example, a company might provide training on new equipment or software to its employees. This would allow the employees to use the new equipment or software more effectively, which would lead to improved productivity and efficiency.

Reducing costs is an essential part of operations and logistics jobs. By identifying areas where costs can be cut, waste can be eliminated, and efficiency can be improved, businesses can improve their bottom line and gain a competitive advantage.

8. Ensuring

Ensuring is a critical aspect of operations and logistics jobs. It involves taking steps to ensure that goods, services, and information are delivered to the right place, at the right time, and in the right condition. This requires careful planning, coordination, and execution.

- Quality Assurance

Ensuring quality is a key part of operations and logistics jobs. This involves setting and maintaining standards for the quality of goods and services, and taking steps to ensure that these standards are met. For example, a company might have a quality assurance process in place to inspect products before they are shipped to customers. This process would help to ensure that the products meet the company’s standards for quality and that they are safe for use.

- Compliance

Ensuring compliance is another important aspect of operations and logistics jobs. This involves making sure that the company is complying with all applicable laws and regulations. For example, a company might have to comply with environmental regulations that govern the storage and disposal of hazardous materials. The company would need to ensure that it is following these regulations in order to avoid fines or other penalties.

- Safety

Ensuring safety is a top priority for operations and logistics jobs. This involves taking steps to protect employees, customers, and the public from harm. For example, a company might have a safety program in place that includes training employees on how to handle hazardous materials safely. The company would also need to have safety equipment in place, such as fire extinguishers and safety glasses.

- Security

Ensuring security is also important for operations and logistics jobs. This involves taking steps to protect the company’s assets from theft, damage, and sabotage. For example, a company might have a security system in place that includes security cameras and motion detectors. The company might also have security guards on patrol to deter crime.

Ensuring is a critical aspect of operations and logistics jobs. By taking steps to ensure quality, compliance, safety, and security, businesses can protect their employees, customers, and the public, and they can also protect their assets and reputation.

Frequently Asked Questions about Operations and Logistics Jobs

Operations and logistics jobs are essential for the smooth functioning of businesses and organizations. They involve planning, organizing, and executing activities to ensure the efficient and effective flow of goods, services, and information. Here are answers to some frequently asked questions about operations and logistics jobs:

9. What are the different types of operations and logistics jobs?

There are many different types of operations and logistics jobs, including supply chain managers, logisticians, operations managers, production planners, inventory control specialists, distribution center managers, and transportation managers.

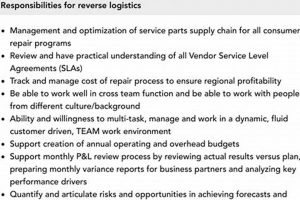

10. What are the key skills required for operations and logistics jobs?

Operations and logistics jobs require a variety of skills, including planning and organizing skills, problem-solving skills, communication skills, and leadership skills. They also require knowledge of supply chain management, logistics, and inventory management.

11. What are the career opportunities for operations and logistics professionals?

Operations and logistics professionals have a wide range of career opportunities. They can work in a variety of industries, including manufacturing, retail, healthcare, and government. They can also work in a variety of roles, including management, consulting, and sales.

12. What is the job outlook for operations and logistics professionals?

The job outlook for operations and logistics professionals is expected to be good in the coming years. The increasing globalization of business and the growing demand for efficient supply chains are expected to drive demand for these professionals.

13. What are the challenges facing operations and logistics professionals?

Operations and logistics professionals face a number of challenges, including the increasing complexity of supply chains, the globalization of business, and the need to reduce costs. They also face the challenge of keeping up with new technologies and trends.

14. How can I prepare for a career in operations and logistics?

There are a number of ways to prepare for a career in operations and logistics. You can earn a degree in supply chain management, logistics, or a related field. You can also gain experience through internships or entry-level jobs in the field.

Operations and logistics jobs are essential for the success of businesses and organizations. They offer a variety of career opportunities for individuals with a variety of skills and interests.

To learn more about operations and logistics jobs, you can visit the website of the Council of Supply Chain Management Professionals (CSCMP) at www.cscmp.org.

Tips for Operations and Logistics Jobs

Operations and logistics jobs are essential for the smooth functioning of businesses and organizations. They involve planning, organizing, and executing activities to ensure the efficient and effective flow of goods, services, and information. Here are some tips for success in operations and logistics jobs:

Tip 1: Develop a strong understanding of supply chain management.

Supply chain management is the process of planning, organizing, and executing the activities involved in the flow of goods and services from suppliers to customers. A strong understanding of supply chain management will help you to identify and mitigate risks, improve efficiency, and reduce costs.

Tip 2: Develop strong communication and interpersonal skills.

Operations and logistics professionals must be able to communicate effectively with a variety of stakeholders, including suppliers, customers, and colleagues. They must also be able to build and maintain strong relationships with these stakeholders.

Tip 3: Stay up-to-date on the latest technology trends.

Technology is constantly changing the way that operations and logistics are managed. Operations and logistics professionals must stay up-to-date on the latest technology trends in order to remain competitive.

Tip 4: Be adaptable and flexible.

The business environment is constantly changing. Operations and logistics professionals must be adaptable and flexible in order to respond to these changes effectively.

Tip 5: Be detail-oriented and organized.

Operations and logistics jobs require a high level of detail orientation and organization. Operations and logistics professionals must be able to manage multiple tasks and projects simultaneously.

By following these tips, you can increase your chances of success in operations and logistics jobs.

Key Takeaways:

- Develop a strong understanding of supply chain management.

- Develop strong communication and interpersonal skills.

- Stay up-to-date on the latest technology trends.

- Be adaptable and flexible.

- Be detail-oriented and organized.

Conclusion

Operations and logistics jobs are essential for the smooth functioning of businesses and organizations. They involve planning, organizing, and executing activities to ensure the efficient and effective flow of goods, services, and information. Operations and logistics professionals play a vital role in ensuring that businesses run smoothly and efficiently, and that customers receive the products and services they need, when and where they need them.

The field of operations and logistics is constantly evolving, as new technologies and trends emerge. Operations and logistics professionals must be adaptable and flexible in order to stay ahead of the curve and continue to meet the needs of businesses and customers. By staying up-to-date on the latest trends and developments, and by developing a strong understanding of supply chain management and logistics, operations and logistics professionals can position themselves for success in this dynamic and growing field.