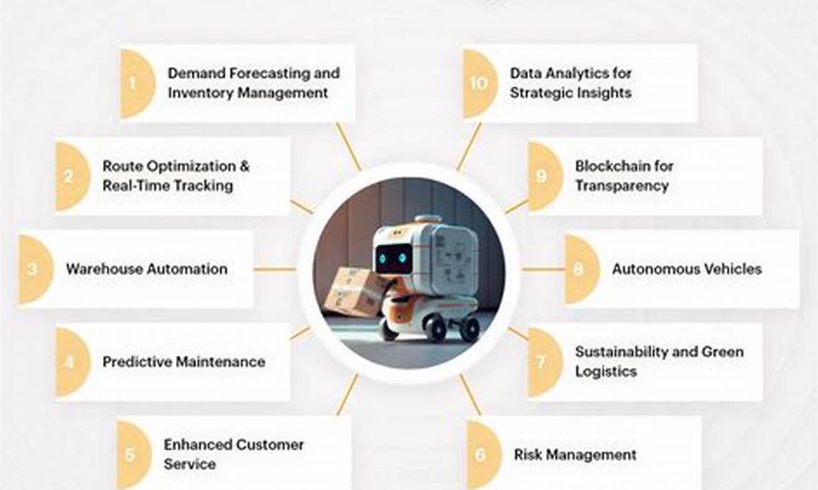

The progression from logistic optimization to artificial intelligence (AI) has revolutionized supply chain management. Logistic optimization involves using mathematical models and algorithms to improve the efficiency and effectiveness of logistics operations, such as inventory management, transportation, and warehousing. AI, on the other hand, encompasses a range of technologies, including machine learning, natural language processing, and computer vision, that enable computers to perform tasks that typically require human intelligence.

The integration of AI into logistic optimization has brought about significant benefits, including improved demand forecasting, optimized inventory levels, reduced transportation costs, and enhanced customer service. For example, AI-powered demand forecasting models can analyze historical data, market trends, and external factors to predict future demand more accurately. This information can then be used to optimize inventory levels, ensuring that businesses have the right amount of stock to meet customer demand without incurring excessive holding costs.

Furthermore, AI is playing a crucial role in the development of autonomous logistics systems, such as self-driving vehicles and robotic warehouses. These systems have the potential to further improve efficiency, reduce costs, and enhance safety in the logistics industry.

1. Efficiency

Efficiency is a key factor in the success of any logistics operation. By automating tasks, optimizing routes, and reducing waste, AI can help businesses to improve their efficiency and profitability.

- Automation: AI can be used to automate a variety of tasks in the logistics process, such as order processing, inventory management, and transportation scheduling. This can free up human workers to focus on more complex tasks, such as customer service and strategic planning.

Example:A large e-commerce retailer uses AI to automate the process of picking and packing orders. This has resulted in a significant increase in efficiency and a reduction in order fulfillment time.

- Optimization: AI can be used to optimize routes for transportation and delivery. This can help businesses to reduce fuel costs, improve delivery times, and reduce emissions.

Example: A logistics company uses AI to optimize the routes of its delivery trucks. This has resulted in a reduction in fuel costs and a decrease in delivery times.

- Waste reduction: AI can be used to reduce waste in the logistics process by identifying and eliminating inefficiencies. This can help businesses to save money and improve their environmental performance.

Example:A manufacturing company uses AI to identify and eliminate waste in its packaging process. This has resulted in a reduction in packaging costs and a decrease in the company’s environmental footprint.

The progression from logistic optimization to AI is a significant development that has the potential to revolutionize the way that businesses manage their supply chains. By leveraging the power of AI, businesses can improve their efficiency, reduce costs, and improve their environmental performance.

2. Accuracy

In the context of the progression from logistic optimization to AI, the accuracy of AI-powered systems is a key factor. AI systems can be trained on large datasets and complex algorithms, which allows them to identify patterns and make predictions with a high degree of accuracy. This is in contrast to human workers, who may be more prone to making mistakes, especially when performing repetitive or complex tasks.

- Demand forecasting: AI-powered systems can be used to forecast demand for products and services with a high degree of accuracy. This information can then be used to optimize inventory levels and production schedules, reducing the risk of stockouts and overstocking.

- Inventory management: AI-powered systems can be used to track inventory levels and identify trends. This information can then be used to optimize inventory levels and reduce the risk of stockouts and overstocking.

- Predictive maintenance: AI-powered systems can be used to predict when equipment is likely to fail. This information can then be used to schedule maintenance and repairs, reducing the risk of unplanned downtime and costly repairs.

- Quality control: AI-powered systems can be used to inspect products and identify defects. This information can then be used to improve quality control processes and reduce the risk of defective products reaching customers.

The accuracy of AI-powered systems is a key factor in the progression from logistic optimization to AI. By leveraging the power of AI, businesses can improve the accuracy of their demand forecasting, inventory management, and other logistic processes. This can lead to significant cost savings and improved customer service.

3. Speed

In the context of the progression from logistic optimization to AI, the speed of AI systems is a key factor. AI systems can process data and make decisions much faster than humans, which can lead to significant time savings in a variety of logistic processes.

- Real-time decision-making: AI systems can be used to make decisions in real-time, without the need for human intervention. This can be critical in situations where time is of the essence, such as in the case of emergency response or fraud detection.

- Automated processes: AI systems can be used to automate a variety of logistic processes, such as order processing, inventory management, and transportation scheduling. This can free up human workers to focus on more complex tasks, such as customer service and strategic planning.

- Predictive analytics: AI systems can be used to analyze data and identify trends. This information can then be used to predict future events, such as demand for products and services. This can help businesses to make better decisions about inventory levels, production schedules, and marketing campaigns.

- Optimization: AI systems can be used to optimize a variety of logistic processes, such as routing and scheduling. This can help businesses to reduce costs, improve efficiency, and reduce emissions.

The speed of AI systems is a key factor in the progression from logistic optimization to AI. By leveraging the power of AI, businesses can save time, improve efficiency, and make better decisions.

4. Scalability

The scalability of AI systems is a key factor in the progression from logistic optimization to AI. As businesses collect more data and face more complex problems, they need AI systems that can handle the increased volume and complexity. AI systems that are scalable can be easily expanded to handle larger datasets and more complex problems, without sacrificing performance.

- Big data: AI systems are becoming increasingly important for analyzing big data. Big data refers to datasets that are too large and complex for traditional data processing tools to handle. AI systems can be used to analyze big data to identify trends, patterns, and insights that would be impossible to find manually.

- Complex problems: AI systems are also becoming increasingly important for solving complex problems. Complex problems are problems that are difficult to solve using traditional methods. AI systems can be used to solve complex problems by finding innovative solutions that would be impossible for humans to find.

- Real-time decision-making: AI systems are also becoming increasingly important for making real-time decisions. Real-time decision-making is the ability to make decisions in real time, without the need for human intervention. AI systems can be used to make real-time decisions by analyzing data and identifying patterns that would be impossible for humans to identify in real time.

- Predictive analytics: AI systems are also becoming increasingly important for predictive analytics. Predictive analytics is the ability to predict future events based on historical data. AI systems can be used to perform predictive analytics by identifying patterns and trends in data that would be impossible for humans to identify.

The scalability of AI systems is a key factor in the progression from logistic optimization to AI. By leveraging the power of AI, businesses can handle larger datasets, solve more complex problems, make real-time decisions, and perform predictive analytics. This can lead to significant benefits, such as improved efficiency, cost savings, and better customer service.

5. Cost-effectiveness

Cost-effectiveness is a key factor in the progression from logistic optimization to AI. AI can help to reduce costs by automating tasks, optimizing operations, and reducing waste. This can lead to significant savings for businesses, which can then be reinvested in other areas, such as research and development or customer service.

There are many examples of how AI is being used to reduce costs in the logistics industry. For example, AI-powered systems can be used to:

- Automate tasks such as order processing, inventory management, and transportation scheduling.

- Optimize routes for transportation and delivery.

- Identify and eliminate waste in the logistics process.

In addition, AI can be used to improve the accuracy of demand forecasting and inventory management. This can help businesses to reduce the risk of stockouts and overstocking, which can also lead to cost savings.

The cost-effectiveness of AI is a key reason why businesses are adopting AI solutions. By leveraging the power of AI, businesses can reduce costs, improve efficiency, and gain a competitive advantage.

6. Sustainability

The progression from logistic optimization to AI has the potential to significantly reduce the environmental impact of logistics operations. AI can be used to optimize routes and reduce waste, leading to lower emissions and a more sustainable supply chain.

- Optimized Routing

AI can be used to optimize routing for transportation and delivery, reducing the distance traveled and the number of vehicles required. This can lead to significant reductions in greenhouse gas emissions and fuel costs. - Reduced Waste

AI can be used to identify and eliminate waste in the logistics process. For example, AI can be used to optimize inventory levels, reducing the amount of waste generated due to overstocking or spoilage. - Improved Sustainability

By optimizing routes and reducing waste, AI can help businesses to improve their overall sustainability. This can lead to benefits such as reduced emissions, lower energy consumption, and a smaller environmental footprint.

The adoption of AI in the logistics industry is still in its early stages, but the potential for sustainability improvements is significant. As AI technology continues to develop, we can expect to see even more innovative and effective ways to reduce the environmental impact of logistics operations.

7. Innovation

The rapid evolution of AI and the constant development of new applications have a significant impact on the progression from logistic optimization to AI. Businesses that embrace AI are in a prime position to leverage the latest advancements and drive innovation within their logistics operations.

- AI-powered automation and optimization

AI is revolutionizing logistics operations through automation and optimization. AI-powered systems can automate repetitive tasks, such as order processing and inventory management, freeing up human workers to focus on more complex and strategic activities. Additionally, AI can optimize processes, such as route planning and scheduling, leading to increased efficiency and cost savings.

- Enhanced decision-making

AI provides businesses with enhanced decision-making capabilities. AI-powered analytics can analyze vast amounts of data to identify patterns and trends, enabling logistics professionals to make informed decisions based on real-time insights. This can lead to better inventory management, improved demand forecasting, and optimized supply chain planning.

- Predictive maintenance

AI is playing a crucial role in predictive maintenance within logistics operations. AI-powered systems can monitor equipment and infrastructure to identify potential issues before they occur. This proactive approach to maintenance can reduce downtime, improve equipment longevity, and minimize disruptions to logistics operations.

- Real-time visibility and tracking

AI is enhancing real-time visibility and tracking capabilities in logistics. AI-powered systems can monitor the movement of goods and assets in real-time, providing businesses with a comprehensive view of their supply chain. This improved visibility enables businesses to respond quickly to disruptions, optimize inventory levels, and enhance customer service.

The continuous innovation in AI is driving the progression from logistic optimization to AI and providing businesses with new opportunities to improve efficiency, reduce costs, and gain a competitive advantage. As AI technology continues to evolve, we can expect to see even more groundbreaking applications and advancements in the field of logistics.

Frequently Asked Questions about the Progression from Logistic Optimization to AI

The progression from logistic optimization to AI is a significant development in the supply chain management industry. AI offers numerous benefits, including improved efficiency, accuracy, speed, scalability, cost-effectiveness, sustainability, and innovation. However, there are some common questions and misconceptions regarding this transition.

Question 1: What is the difference between logistic optimization and AI in logistics?

Logistic optimization involves using mathematical models and algorithms to improve the efficiency of logistics operations, while AI encompasses technologies like machine learning and natural language processing that enable computers to perform tasks typically requiring human intelligence.

Question 2: How does AI improve efficiency in logistics?

AI can automate tasks, optimize routes, and reduce waste. For example, AI-powered demand forecasting can improve inventory management, reducing the risk of stockouts and overstocking.

Question 3: Is AI more accurate than humans in logistics operations?

Yes, AI-powered systems can be more accurate than humans in performing tasks such as demand forecasting and inventory management. AI can analyze large datasets and identify patterns that may be missed by humans.

Question 4: How does AI contribute to sustainability in logistics?

AI can optimize routes and reduce waste, leading to lower emissions and a more sustainable supply chain. For example, AI-powered routing can reduce the distance traveled and the number of vehicles required for transportation.

Question 5: Is it expensive to implement AI in logistics operations?

While AI implementation costs can vary, the long-term benefits often outweigh the initial investment. AI can improve efficiency, reduce costs, and enhance customer service, providing a strong return on investment.

Question 6: Will AI replace human workers in logistics?

AI is not intended to replace human workers but rather to augment their capabilities. AI can handle repetitive and complex tasks, allowing human workers to focus on higher-level activities that require strategic thinking and creativity.

In summary, the progression from logistic optimization to AI brings significant benefits to the supply chain management industry. AI enhances efficiency, accuracy, speed, scalability, cost-effectiveness, sustainability, and innovation. By embracing AI, businesses can gain a competitive advantage and drive continuous improvement in their logistics operations.

Transition to the next article section: Exploring the applications of AI in various logistics processes

Tips for leveraging the progression from logistic optimization to AI in your business

The progression from logistic optimization to AI offers significant opportunities for businesses to improve their supply chain management operations. By implementing these tips, businesses can harness the power of AI to drive efficiency, accuracy, speed, scalability, cost-effectiveness, sustainability, and innovation.

Tip 1: Identify high-value processes for AI implementation

Start by identifying the areas in your logistics operations that would benefit most from AI. Consider processes that are repetitive, data-intensive, or require complex decision-making, such as demand forecasting, inventory management, or route optimization.

Tip 2: Choose the right AI technology for the task

Not all AI technologies are created equal. Research different types of AI, such as machine learning, natural language processing, or computer vision, to determine which is most suitable for your specific needs and goals.

Tip 3: Ensure data quality and availability

AI algorithms rely on data to learn and improve. Ensure that you have access to high-quality, structured data that is relevant to the AI implementation. Invest in data cleaning and data preparation to ensure the accuracy and reliability of your AI models.

Tip 4: Collaborate with AI experts and vendors

If you lack in-house AI expertise, consider partnering with AI consultants or vendors. They can provide guidance on AI implementation, technology selection, and best practices. Collaboration can accelerate your AI adoption and ensure successful outcomes.

Tip 5: Monitor and evaluate AI performance

Once you implement AI solutions, it’s crucial to monitor their performance and make adjustments as needed. Establish metrics to track key performance indicators (KPIs) and measure the impact of AI on your logistics operations. Regular evaluation ensures that your AI systems continue to deliver optimal results.

Tip 6: Invest in employee training and upskilling

AI implementation may require your employees to adapt to new technologies and processes. Invest in training and upskilling programs to ensure that your workforce is equipped with the necessary knowledge and skills to work effectively with AI systems.

Tip 7: Consider the ethical and regulatory implications of AI

As AI becomes more prevalent in logistics, it’s essential to consider its ethical and regulatory implications. Ensure that your AI systems are developed and deployed in a responsible manner, respecting data privacy, algorithmic fairness, and potential biases.

Tip 8: Stay updated on the latest AI trends and advancements

The field of AI is constantly evolving. Stay informed about the latest advancements and trends in AI technology. Attend industry events, read research papers, and explore new AI applications to continuously improve your AI implementation and drive innovation in your logistics operations.

By following these tips, businesses can effectively leverage the progression from logistic optimization to AI and unlock its full potential to transform their supply chain management processes, gain a competitive advantage, and achieve operational excellence.

Transition to the article’s conclusion: Exploring the future of AI in logistics and its continued impact on the industry

Conclusion

The progression from logistic optimization to AI has revolutionized the supply chain management industry, offering immense opportunities for businesses to improve efficiency, accuracy, speed, scalability, cost-effectiveness, sustainability, and innovation. By leveraging AI technologies, businesses can automate tasks, optimize processes, enhance decision-making, and drive continuous improvement in their logistics operations.

This transition requires thoughtful planning, careful implementation, and a commitment to innovation. Businesses that embrace AI and invest in its strategic deployment will gain a competitive advantage and position themselves for success in the rapidly evolving logistics landscape. AI will continue to play a transformative role in logistics, bringing forth new advancements and applications that will further enhance the efficiency, resilience, and sustainability of global supply chains.